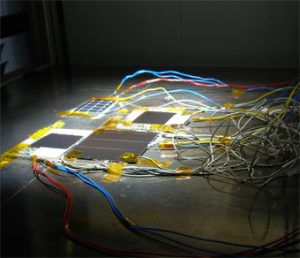

Fig. 1 – Solar cell tester for life-time testing of novel thin film solar cells in the SERG laboratory.

Achieving low cost, non-toxic, high efficiency, high throughput solar cells is the ultimate challenge for the solar energy industry. Traditional glass laminate crystalline silicon solar cells offer relatively high efficiency (up to 20%) but are an expensive product. At SERG research and development of low cost sputtered amorphous silicon solar cells on flexible substrates is being conducted.

The project is a collaboration of three organisations Plasma Quest Ltd (PQL), SERG and Romag Ltd.

Hydrogenated amorphous silicon (a-Si:H) semiconducting layers are deposited onto glass/ITO (Indium tin oxide) using the patented technology from Plasma Quest Limited, known as Hi Target Utilisation Sputtering (HiTUS) technique.

This technology is a low cost sputtering process which is non-toxic and operates at low temperatures. This deposition technique is capable of producing very high quality thin film materials with excellent reproducibility, very low stress and excellent adhesion, whether on metal, glass or plastic substrates. The characterisation and optimisation of the solar cells is conducted by PQL and SERG.

Light soaking tests to assess the stability and the I-V characteristics to measure the efficiency of the solar cells are being conducted with the custom built device shown in Figures 1 and 2.

The group will also be working alongside Romag Ltd on the electrical connectivity and encapsulation of the solar cells once the optimised semiconducting layers are deposited onto flexible substrates.

Poster presented at the 23rd European Photovoltaic Solar Energy Conference and Exhibition: View the poster here

Poster title: A comparative study of low hydrogenated amorphous silicon with commercially available thin film silicon solar cells.